The British

Racing Motors (unofficial)

information centre.

The British

Racing Motors (unofficial)

information centre. The British

Racing Motors (unofficial)

information centre.

The British

Racing Motors (unofficial)

information centre.

- the engines - H16 - the mighty beast !

H16 3 litre P75 engine - total production six standard, two 4-valve magnesium/titanium and two 4.2 litre Indianapolis units.

25 October 2001 at www.doningtoncollection.com The 4 valve H16 engine that was the last development of the engine - but was never raced.

|

The H16 is often

thought of as a glorious failure. In part, that may be

the case. It was also a great

British winner. The engine triumphed at the 1966 US

Grand Prix with the Lotus 43 - BRM H16. The H16 is often

thought of as a glorious failure. In part, that may be

the case. It was also a great

British winner. The engine triumphed at the 1966 US

Grand Prix with the Lotus 43 - BRM H16.During most of the 60’s the only obstacle to a string of BRM world championships was the Lotus / Clark partnership. It is a dramatic twist to the rivalry that this partnership helped the H16 to victory. It should also be remembered that while running the H16 the team worked on the BRM V8, Westlake V12, Matra V12 and their own BRM V12 - all race winners at one time or another! (Photograph - BRM Track Day, Blyton - 22 April 2015) ..................... More Photos in my Flickr album - BRM Track Day - Blyton 22 April 2015) |

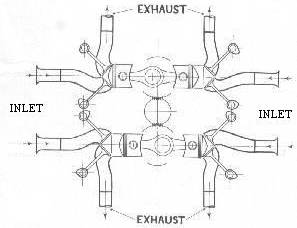

How the H16 should have been. This cross section shows - six camshafts - directly linked crankshafts - low centre of gravity - a very solid "lump" to support the rear suspension. |

How the H16 was raced. This cross section shows - eight camshafts - gear to link the two crankshafts - higher centre of gravity - a more flexible "lump" to support the rear suspension. |

The choice of engine format for the 1966 three-litre formula was not a straightforward choice for BRM.

They believed they already had the perfect F1 configuration in the centre-exhaust 2-valves per cylinder 1.5 litre V8. Keeping the 187.5 cc cylinder size meant 16 cylinders for 3 litres. The H16 in the form of two flat-8s, one on top of the other would give a solid and compact unit capable of being used as a stressed member supporting the rear suspension.

At the same time a BRM – Harry Weslake partnership, based at Rye and including BRM designer Peter Berthon, was pressing very hard for a 4-valves per cylinder V12. A 12-cylinder engine would be a more simple, inexpensive and reliable option. It would be difficult to use as a stressed part of the car, being too long and narrow.

The decision took from December 1964 until well into 1965 to be made. In May 1965, Sir Alfred Owen ruled that BRM at their Bourne base would build the 2-valves per cylinder H16 and that the Berthon-Weslake company would build a 4-valves per cylinder V12. The works team would use the better one for the 1966 season. Weslake were to build a single cylinder research engine for each project. A 250 cc one for the V12 and a 187.5 cc one for work on a later 4-valves per cylinder head for the H16.

In July 1965 it had been agreed to supply leased H16 engines to Lotus for the new formula. Later, Lotus asked for 4.2litre alcohol-fuelled engines for Indianapolis. The agreement to supply F1 engines to Lotus as well as the works team was just a matter of making some extra engines to the standard specification. The Indi project required a large additional development programme to the detriment of the F1 effort. (As things turned out the 4.2 unit was never raced).

In late 1965 the Weslake 250cc. single-cylinder was reported to be giving nearly 40 bhp. - 158 bhp. per litre. Before the V12 could find its way into a BRM chassis, Harry Weslake bought-out Rubery Owen from the partnership. Sir Alfred was keen to build a less complex 3litre engine for sale, and he directed that when H16 work eased off they should build their own V12 3litre engine for sale for sports car racing.

Due to the difficulty of circulating water between the lower to the upper cylinder heads of the H16 and worries over the ability to produce the complex castings successfully the engine was redesigned to a less risky but less efficient format. As it was Tony Rudd blamed “violent and destructive crankshaft vibration” for mechanical failures during the cars development from early 1966 to the cars first competitive outing at practice for the Monaco GP. Inertia weights were bolted and welded to crankshaft balance weights – throughout 1966 engines were destroyed when the weights flew off over-revved or “tired” units. The early development engine weighed 555 lb. with a further 118 lb of the gearbox and clutch.

A BRM designed 6-speed gearbox was bolted on to the rear of the engine and at the back of that the clutch was encased in a bell-housing. The engine output shaft from the lower crankshaft ran through the gearbox casing to the hydraulically operated clutch, which then returned the drive forward to the gearbox.

The engine was designed as a stressed member supporting the rear suspension First used by Vittorio Jano for the front-engined Lancia D50 V8, BRM lead what was to become universal F1 practice within a few years. A cast-alloy bulkhead between the engine and supported the rear suspension. The riveted aluminium chassis finished immediately behind the driving seat in a flat bulkhead to which the engine was mounted by means of four arms machined from solid duralumin, two each above and below the engine. The Lotus 43 had its four attachment arms fabri≠cated from sheet steel and a fabricated sheet steel hoop that running under the gearbox to support the rear suspension.

With the cylinder heads having the same valve layout as the last of the l.5 litre V8 B.R.M. engines, the H16 had inlet ports between the camshafts on the sides of the engine and exhaust ports above and below the engine. A Lucas fuel-injection unit was mounted on each side of the engine, between the inlet ports, and driven by toothed-belt from an extension of an idler gear-shaft in the gear-train between crankshaft and camshafts, the left-hand shaft also driving an alternator by a second toothed-belt. Transistor ignition is used with a double-ended distributor mounted on the front of the engine. Four throttle-slide plates were coupled in pairs on each side of the engine, with Bowden cables running forward along each side of the cockpit. These cables are joined to a cross-shaft mounted on the scuttle above the pedals.

BRM had two gearbox oil coolers, one on each side of the box but Lotus had one only built into the bodywork over the engine.

Specification - early 1966

Cylinders - 16 cylinders in

“H” formation as two “flat” eight cylinders

one above the other.

Bore - 68.95mm.

Stroke - 48.89mm.

Cubic Capacity - 2,999cc.

Power - 400bhp. at 10,000 rpm. (was this a little

optimistic?)

Valve gear - four camshafts on each side of the engine –

two valves per cylinder.

Fuel Injection - Lucas port fuel injection

Ignition - Lucas transistor ignition with one 10mm. sparking

plug per cylinder

Engine weight - 555 lb.

Gearbox & clutch - 118 lb.

The power band was not too wide - 280bhp. @ 7,500rpm. and 395bhp. @ 10,250rpm. The best figure for the standard engine was 420bhp. for the 1967 Italian GP. An engine rebuild was reputed to take two mechanics three weeks!

In Autumn 1966 BRM was authorised to produce a 2-valve V12 for sports racing cars aiming for 400 bhp. at a weight of 325 lb. Geoff Johnson was allocated to the project to make one and a half simplified Tasman V8s into a 12-cylinder 3 litre.

At the end of the 1966 season a new crankshaft was produced to deal with the vibration problems. A two-pin crank H16 weighed 508 lb.

Over the winter a “B” team was set up to be run by Tim Parnell to run cars and drivers as an addition to the main Works effort.

Between the designing and building the “customer” V12 BRM were also designing the Matra V12 around Matra’s 4-valve head design. BRM’s “all British” involvement in the “all French” project came to an end for political reasons but had been another distraction from H16 development

Secification - mid 1967

Cylinders - 16 cylinders in “H” formation as

two “flat” eight cylinders one above the other.

Bore - 69.88mm.

Stroke - 48.89mm.

Cubic Capacity - 2,996cc.

Power - 405bhp. at 10,500rpm.

By the middle of 1967 the team decided to build a “works” car using their own “customer” engine but sub-contracted the design and building of the first two cars to Len Terry’s company - initially to run with a 2.5 litre versions of the V12 in the 1968 Tasman series. Once authorised by Sir Alfred Owen his new project appeared to take priority over H16 development.

Work started on a lightweight 4 valves per

cylinder H16 with a target power of 500 bhp. and weight of 400 lb.

Tony Rudd commented in his book “It Was Fun” ---

“It had a very narrow included-angle valve gear of 13

degrees. This was made possible by saving space around the

sparking plug boss. Instead of surrounding the deeply recessed

plug with cast aluminium, to retain the coolant, we used a very

thin stainless steel sleeve pressed in place. This enabled us to

move the pair of camshafts 1.25 inches (32 mm) closer together.

It had a large squish deck, with half the combustion chamber in

the piston. Roller-bearing steel camshafts were carried in

magnesium alloy trays. The crankcase was two large magnesium

castings, sandwiching five titanium blocks, which carried the

main bearings. The whole structure was held together by long

bolts, which passed right through the engine from one cylinder

head to the other, and, having learned our lesson, it had short

connecting rods. It met the weight target, but the separate

stainless-steel tube and plastic inlet-manifolds and slides cost

us our power target. We learned there was a relationship between

port length and where they diverged. The Honda solution was to

use two valves in one big port. We did not see much over 420 hp,

although at 398 lb (180.5 kg) it met the weight target. I had

spent nearly £40,000 on this engine - about 40 per cent of my

budget!”

Sir Alfred Owen decided to run the Len Terry V12s for the 1968 season with full 3litre engines. The V12 era started with Tim Parnell as team manager for the winter Tasman series with drivers Bruce McLaren and Pedro Rodriguez using 2.5litre engines.

An H16 was taken to the South African GP in early 1968 for Mike Spence in the engines last competitive use.

Tony Rudd commented in his book “It Was Fun” --- “I wondered what would have happened if we had built the 390 hp 2-valve V12 first. We would have had it ready for Monte Carlo or Spa in 1966. It would have given the 360 hp Repco-Brabham a good run in 1966. We might even have been strong enough to challenge the 420 hp Lotus-Cosworths of 1967 and still have had Graham and Jackie. I also realized if I had had more courage designing the H16 it would have been much lighter and it would have been ready to race three or four months earlier.”

V1.4 - 25 April 2015 ---- recommended resolution (1366 x 768)

© David Hodgkinson 2000-2015. All rights reserved.